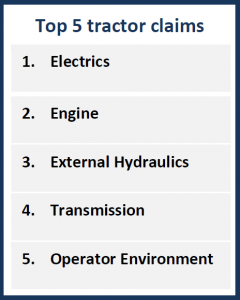

Top 5 Causes of Tractor Breakdowns

Machine Guard research reveals top 5 causes of tractor breakdowns…and how to prevent them.

To download a PDF version of this report, please click here.

Ever since the early pioneers, Henry Ford and Harry Ferguson developed the early petrol driven tractors in the early 1900s they have been the workhorse of agriculture. Of course, breakdowns happen and for over a century many repairs were carried out on the farm. In recent years, the sophistication of modern machinery has meant that this is neither safe nor possible.

Downtime for agricultural equipment is both costly and frustrating. Using our own claims data, we have identified the top 5 reasons why tractors are likely to fail and how to mitigate the risks.

1. Electrics

Modern tractors are complex pieces of kit, and sophistication can lead to electrical failures which are number one on our breakdown list. However, there are a number of things you can do to reduce the risk.

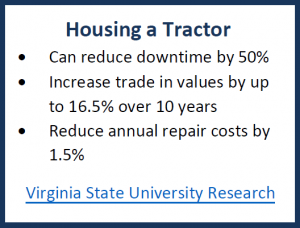

Service, Service, Service – Regular servicing is essential and not just to prevent electrical malfunctions. Manufacturers include scheduled services for a reason, which should not be ignored. Also, in the longer-term there is the additional benefit that the resale value will be maintained. Regular servicing will also help spot potential problems well in advance – before they hit you in the pocket.

Play your part – Keep up to date with checks in the manual. These are often overlooked. Many of these are daily, weekly and at various hourly intervals – all of which should be observed. Conduct regular visual inspections to ensure that no – wires or components are at risk of, rubbing, or melting against hot areas, like the exhaust.

Keep it real – Electrical components should not be considered in isolation, it’s important to look at the vehicle as a whole. For example, failing to replace oil and filters can have a knock-on effect to other systems of the vehicle. Genuine parts must be used for all routine and scheduled servicing and repairs as this is essential for the validation of extended warranty.

2. Engine

The costs for repairing modern engines can escalate rapidly and it makes financial sense to look after the heart of your tractor which is the second most likely failure we see. There are a number of key things to look out for.

Enhancement products – Increasing engine performance beyond its designed specification will invalidate your insurance and could damage key components of the tractor/machine. If you need more performance or power – then invest in a specification that meets your demands.

Quality fuel – Correctly stored helps to reduce fuel related issues, such as blockages, poor performance, higher operating cost, and increased down time. One example is filling up with marine grade diesel.

The increase in renewable alternative fuels can be good for the environment but requires correct storage to mitigate against risks such as bacterial growth, oxidisation (which clog filters) and a build-up of water.

During winter storage of a seasonal machine, it is good practice to fill the fuel tank as this reduces the risk of condensation and moisture build up.

Be kind to your turbo – We all need a break but it’s important to remember that so does your turbo when you stop for a cuppa. An immediate hot shut down from 40,000 revs to zero can cause serious damage – so reduce the turbo speed and let your engine idle before keying off.

3. Hydraulics

A slow or sluggish hydraulics system is both frustrating and a sign that more serious problems may be around the corner. It is important to act on any early warning signs and have it checked out by a trained technician. By neglecting this step, it could lead to a major failure, or worse, shortening the life of the hydraulics system and other related components.

Keep it clean – Introducing dirt and soil into the system is easily done yet easily prevented with a little care. Coupling and uncoupling a trailer can be a common occurrence but must be given due consideration. A little care will prevent the introduction of dirt into the system. Having a clean cloth handy to give the components a quick wipe down will take you a few seconds and potentially save you the cost of a hydraulics repair running into thousands. For a more thorough cleaning an airline clean is advisable.

Servicing and Maintenance – Keeping up with the correct service intervals is important for all major systems such as the engine, transmission, hydraulics, operator environment and the electrics of the vehicle.

4. Transmission

The importance of adhering to the manufacturer’s recommended servicing cannot be underestimated when it comes to the transmission of your tractor/machine. Strictly following the schedule can help reduce the risk of breakdowns and major failures. By neglecting to follow and adhere to the recommendation can lead to unwanted costs and down time especially for complex systems such as hydrostats.

Under pressure – A hydrostatic transmission is a high-pressure system. As a result, oil cleanliness needs to be 100%. We see many transmission failures linked to oil, poor servicing, and maintenance.

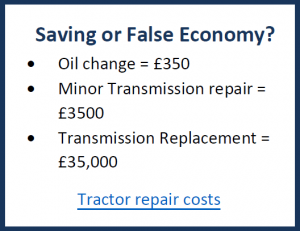

Prevention is cheaper than cure – Not changing the oil and filters might seem like a saving but our claims data proves otherwise. A minor transmission repair could cost £3,500 with a complete replacement coming in at £35,000 – over 100 times more than a £350 oil change!

5. Operator Environment

Whether it is the seat, switches, climate control or lights – there is a duty of care to protect the driver and the public. Injuries to a member of staff can lead to an Employers’ Liability claim and to third parties a Public Liability claim.

Breathe easily – Cab environmental filters need to be checked and changed regularly according to the manufacturer’s manual. Whether this is annually or every 1200 hours, it is just as important to stick to these as changing any other filter. Health and well-being cannot be repaired as easily as a mechanical part. Also, it is important to use the correct filters for the work involved – e.g. crop spraying can require specific filters.

Clean properly – While dirt and soil are part of farm work, so too is keeping tractors ‘ship shape.’ However, going too heavy with the steam cleaner can be as bad as doing nothing as it can lead to excessive water ingress and potential damage. Go carefully.

See and be seen – agricultural work involves unsociable hours. It is important to have all lighting including flashing beacons, cab glass and mirrors kept clean and in good working order.

What next?

However careful you are, breakdowns can still happen – which is why a specialist warranty cover is a wise investment to get you up and running quickly and protect your bottom line.

We can help with all of your machinery warranty and equipment warranty needs so please get in touch on support@machine-guard.com or call us on +44 (0)333 247 0205.

Farming UK Profiles Our Tractor Report

Farming UK’s coverage of our research into the causes of tractor breakdowns and repairs is available here.

Machine Guard Supports #Farm24

As the leading agricultural machinery extended warranty provider, Machine Guard is delighted to support Farmers Guardian’s #Farm24. Find out more […]